From catwalks to keystrokes: How digital innovation is transforming bridge inspections

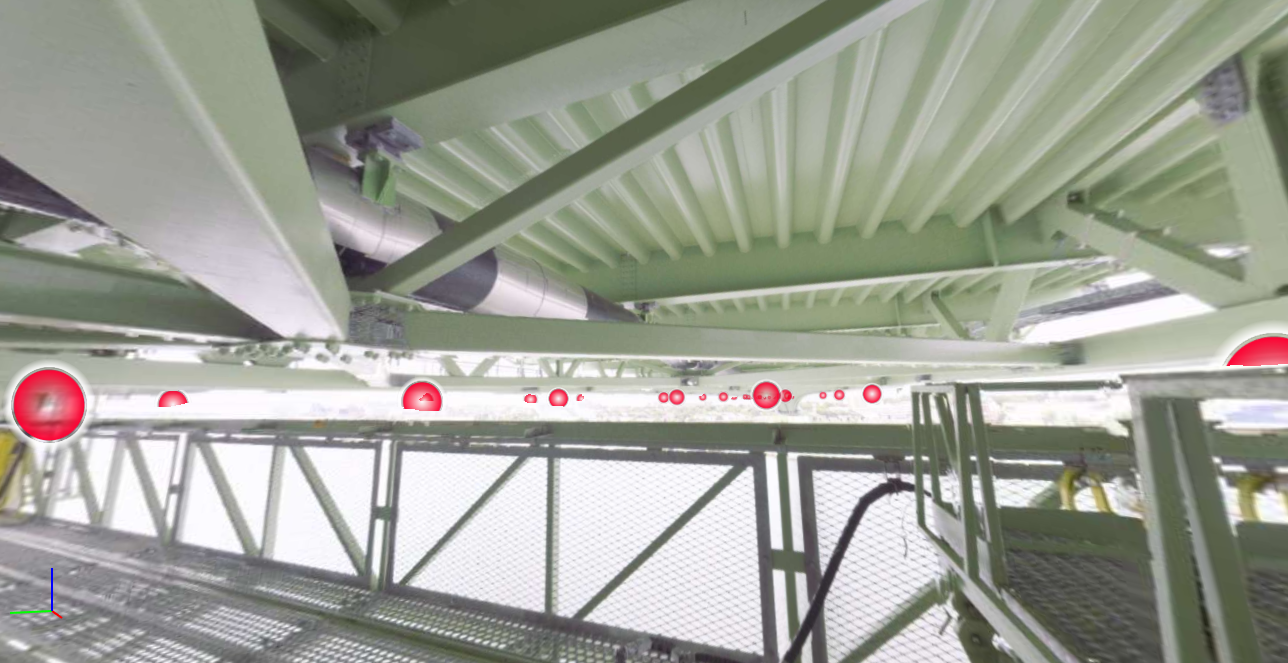

Five years ago, if Ahsan Chowdhury wanted to know the condition of a hanger bolt on the Macdonald Bridge, he’d have to ask team members to strap on their safety gear and send them on the catwalks that run along the underside edges on the 1.2-kilometre bridge.

Depending on the time of day or location of the hanger, safety considerations might require a lane closure – or perhaps the temporary closure of the bridge.

With 40,000 vehicles a day depending on the bridge each day, the Halifax Harbour Bridges chief engineer understands bridge closures can only be done when absolutely necessary. As a regular bridge user himself, he has endured the traffic chaos that can come from even the best-planned closure.

But Chowdhury is conflicted. It’s his job to make sure the aging bridges are structurally safe and in good working order to provide safe and efficient harbour crossings. That requires his team to understand the condition of the thousands of pieces that fit together to keep the suspension bridges safely in place 60 meters above Halifax Harbour.

“It is a very complex structural arrangement when the bridge deck is hanging from a cable, rather than sitting on a solid foundation,” Chowdhury says. “Inspection, evaluation and maintenance of a suspension bridge is very challenging compared to other short- or mid-span bridges.”

A mountain of paperwork

“We were doing inspections and had filing cabinets full of spreadsheets and memos about various parts. We knew what we were doing but we did not have a unified view of everything that was happening.

“I became concerned about what might happen if a member of the team moved on and we lost their institutional knowledge.”

Since 2017, Chowdhury and his team have been working to digitally detail every part of the Macdonald Bridge by creating an image inventory with relevant data. Whenever they carried out an inspection, the part or system was photographed, its condition was noted, and a suggested re-inspection date was determined based on its condition and its role.

The information was loaded into a software program designed specifically for Halifax Harbour Bridges. It also logs the name of the inspector and the date and time of the inspection. Any time further work was carried out, the details were documented digitally and added to the system.

A half-decade in the making

After thousands of inspections over five years, the engineering team now has a detailed digital model of the Macdonald Bridge engineering workings with its Bridge Information Model and Management Systems – or BIMMS.

If there is a report of a problem in a section of the bridge, with a few keystrokes, any team member can zoom in on that section and get details about the parts and systems in the impacted area, look at the last recorded photo and call up the most recent inspection report.

“It is saving us considerable time and money as it allows us immediate access to information that was stored in separate locations previously,” Chowdhury says.

“It also improves our inspection processes by creating a detailed schedule based on the information provided during the on-site visits.”

There are daily, monthly, and annual inspections of bridge engineering works, but not all parts need to be part of every inspection, according to Chowdhury. Some bridge components that are critical and subject to wear and tear, or exposure to the elements, are inspected more frequently. Aspects that are fixed in place or contained a bridge tower may only be inspected once every few years.

Next up: MacKay Bridge and some 3-D magic

With the digital model of the Macdonald Bridge now complete, the effort will be repeated with the MacKay Bridge. In addition, with the help of the bridge’s IT department, the final phase of the BIMMS program will see all of the information incorporated to create a 3-D interactive model that will allow engineers to get a visual view that would otherwise be impossible to get.

“People may look at the bridges and see industrial-era engineering, but we are doing leading-edge work, Chowdhury said. “This is ground-breaking in bridge circles and HHB is asked to speak about it at conferences across the world.”